Carved Edge: Precision Perimeter Texture

In a world saturated with smooth, homogeneous surfaces, the human hand and eye seek something more. We are drawn to details that break the monotony, that invite touch, and that whisper a story of craftsmanship. This is where the carved edge and its companion, precision perimeter texture, step into the spotlight. Far more than a simple decorative flourish, this design element is a sophisticated interplay of aesthetics, ergonomics, and engineering intent. It is the deliberate interruption of a plane, a calculated pattern etched into the boundary of an object that transforms it from a mere tool or device into an object of interaction and desire.

Beyond the Bevel: Defining the Carved Edge

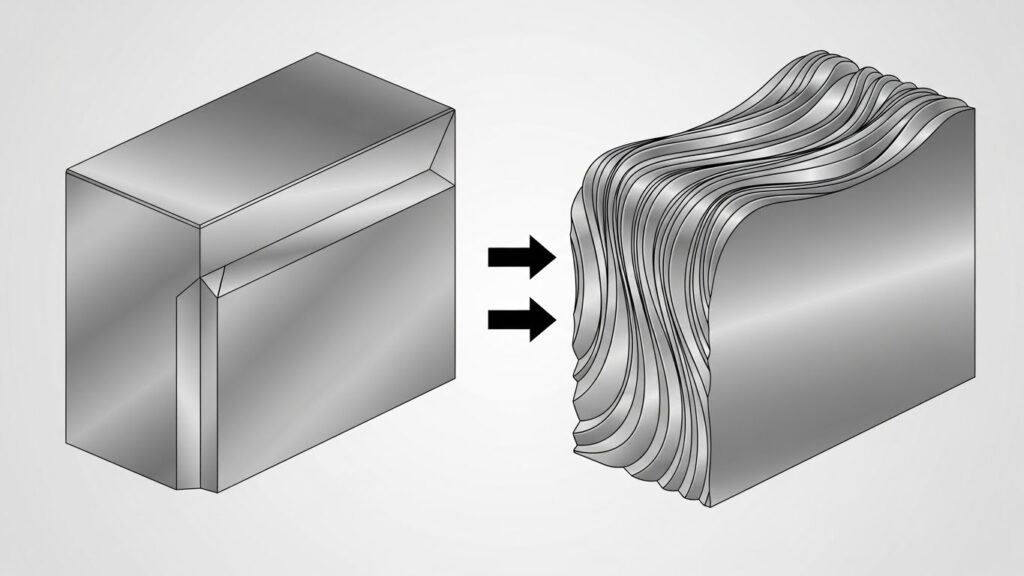

First, let’s distinguish a carved edge from a simple bevel or chamfer. A bevel is a flat, angled surface cut along an edge, primarily for safety, durability, or to facilitate assembly. A carved edge, however, is defined by texture and pattern along that perimeter. It involves removing material or adding detail in a consistent, intentional sequence to create a specific tactile and visual experience.

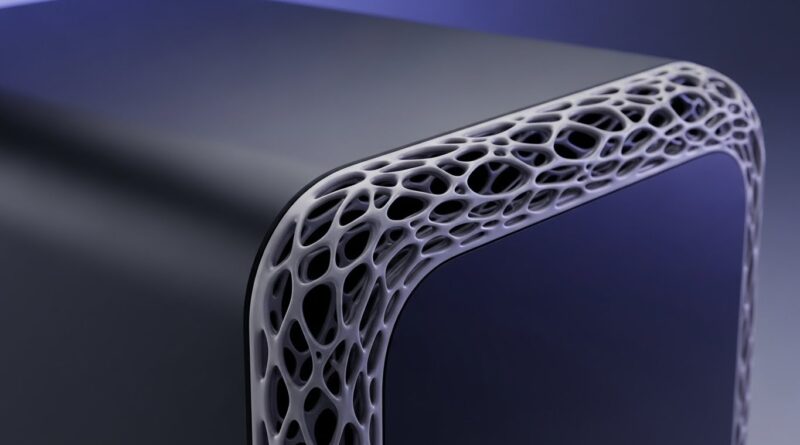

Think of the knurled grip on a vintage camera lens or a precision tool—a classic example of perimeter texture for enhanced grip. Now, imagine that principle elevated and refined. Modern carved edges can feature micro-pyramids, linear grooves, wave patterns, dot matrices, or even custom logos repeated along the edge. This isn’t just about grip; it’s about creating an identity, guiding interaction, and injecting character into the very silhouette of an object.

The Engineering of Tactility: How Precision Perimeter Texture is Created

Achieving a flawless carved edge demands high-precision manufacturing techniques. The consistency of the pattern, its depth, and the sharpness of each microscopic feature are what separate a premium feel from a cheap imitation.

CNC Machining is the most common method for creating carved edges in metals, engineered plastics, and wood. Using specialized cutting tools—like ball-nose end mills for rounded grooves or V-bits for sharp lines—the machine follows a digital blueprint with micron-level accuracy. This allows for incredibly complex and repeatable patterns. Precision Grinding and EDM (Electrical Discharge Machining) are also used for exceptionally hard materials or intricate details.

For mass-produced consumer goods, injection molding is key. The texture is machined in reverse into the mold’s steel cavity. When molten plastic is injected and cools, it perfectly replicates the carved edge pattern. The quality of the final product hinges entirely on the precision of the mold itself, making the initial tooling a critical investment.

Form Meets Function: The Multifaceted Role of Texture

The application of a carved edge is never arbitrary. It serves a spectrum of purposes, often simultaneously.

Enhanced Grip and Ergonomics: This is the most practical function. A textured perimeter on a smartphone, remote control, or power tool provides a secure, non-slip surface. It subtly guides the user’s fingers to the correct holding position, improving comfort and reducing fatigue and error.

Visual Delineation and Aesthetics: A carved edge breaks up large, blank surfaces, adding visual interest and shadow lines that change with the viewing angle. It can make a product look thinner, more dynamic, or more refined. It acts as a frame, drawing attention to the device’s form or its interface.

Perception of Quality and Durability: Our sense of touch is directly linked to our judgment of quality. A precise, consistent texture feels expensive and well-made. It signals that attention was paid to the smallest detail, implying that the overall product is robust and reliable.

Brand Differentiation: In crowded markets, a signature carved edge can become a recognizable brand identifier. It’s a tactile logo, a unique feature that competitors cannot easily copy without appearing derivative.

Carved Edges in Action: Industry Applications

The use of precision perimeter texture spans from the tech you use daily to the furniture in your home.

Consumer Electronics: This is perhaps the most visible arena. High-end laptops, smartphones, tablets, and game controllers often feature subtle linear or dot-pattern edges for grip and style. It’s a detail that makes unboxing a new device feel premium.

Industrial Design & Tools: Here, functionality reigns. Knurling on wrenches, textured grips on surgical instruments, or patterned edges on control panels are crucial for safe, positive operation, often with gloved hands.

Automotive Interiors: Look at the edge of a gear shift knob, the rim of a steering wheel, or the controls on the center console. Carved edges provide tactile feedback without requiring the driver to look away from the road.

Architectural Hardware & Furniture: Door handles, cabinet pulls, and the edges of tables or shelves can incorporate textured perimeters. This adds an element of craft, prevents fingerprints on smooth surfaces, and ensures a solid grip.

The Design Considerations: Not Just a Pretty Pattern

Implementing a successful carved edge requires careful thought. Pattern Scale and Depth: The texture must be pronounced enough to be effective but not so aggressive that it feels rough or collects dirt. Directionality: Vertical grooves might enhance up-down grip, while horizontal patterns could improve lateral hold. Material Compatibility: The chosen pattern must be suitable for the material’s properties—brittle materials may not support fine, sharp details. Cost vs. Benefit: More complex textures increase machining or mold-making time and cost. The design must justify this investment through added value.

Furthermore, the carved edge must be integrated into the overall design language. It should feel like a cohesive part of the object, not an afterthought. Its rhythm and geometry can echo other design elements, creating a harmonious visual and tactile narrative.

The Future of the Edge: Innovation and Sustainability

As technology advances, so do the possibilities for perimeter texture. Additive manufacturing (3D printing) allows for previously impossible internal channels and organic, gradient textures that can be optimized for weight, strength, and feel. We are also seeing the rise of multi-material processes, where a soft-touch elastomer with a texture is overmolded onto a rigid substrate, combining comfort with precision.

Sustainability is also becoming a factor. Designers are considering how textured edges affect a product’s end-of-life. Can the textured part be easily separated for recycling? Does the pattern allow for the use of less material while maintaining structural rigidity? The carved edge of the future may be as much about eco-efficiency as it is about ergonomics.

Conclusion: The Detail That Defines Experience

The carved edge and precision perimeter texture represent a beautiful convergence where engineering discipline meets artistic sensibility. It is a testament to the idea that the most profound interactions often happen at the margins. This detail, often measured in fractions of a millimeter, has the power to transform a user’s relationship with an object, building trust, delight, and loyalty through the simple, yet profound, language of touch.

In an increasingly digital and flat world, the crave for physical texture and tangible quality only grows stronger. The carved edge is a direct response to that craving—a deliberate, precise, and human-centric detail that reminds us that the objects we use are made, and well-made objects tell their story through every surface, especially the edge.