Carved Surface: Precision-Textured Throughout

Imagine running your fingers across a surface. Instead of a flat, monotonous plane, you feel a landscape of deliberate ridges, valleys, patterns, and pores. This is not a random imperfection; it is a carved surface, a testament to controlled creation. The phrase “precision-textured throughout” elevates this concept from mere decoration to a fundamental design philosophy. It speaks to a consistency and intentionality that permeates an entire object, transforming its very essence—how it interacts with light, how it feels to the touch, how it performs its function. This is where material science meets artistry, and the results are revolutionizing fields from aerospace to architecture, consumer electronics to medical devices.

Beyond Decoration: The Functional Power of Texturing

For centuries, surface texturing was primarily an aesthetic pursuit—the ornate carvings on wooden furniture, the engraved patterns on ceremonial armor. Today, while beauty remains a key driver, the purpose has dramatically expanded. A precision-textured surface is first and foremost an engineered solution. In industrial applications, micro-textures can reduce friction between moving parts, enhancing efficiency and longevity. In automotive design, specific textures on interior panels can mitigate glare, dampen sound, and provide a superior tactile experience. In the medical field, textured surfaces on implants are not an afterthought; they are critical for osseointegration, allowing human bone to bond securely with the artificial component.

The keyword here is “throughout.” A texture applied only to a portion of a surface can create points of stress, visual inconsistency, or functional failure. Precision-texturing throughout ensures uniform performance. It means every square millimeter of the surface is contributing to the overall goal, whether that goal is to shed water more efficiently, grip more securely, or scatter light in a specific way. This holistic approach demands advanced manufacturing techniques and a deep understanding of the material’s behavior at a microscopic level.

The Tools of Creation: How Precision Texturing is Achieved

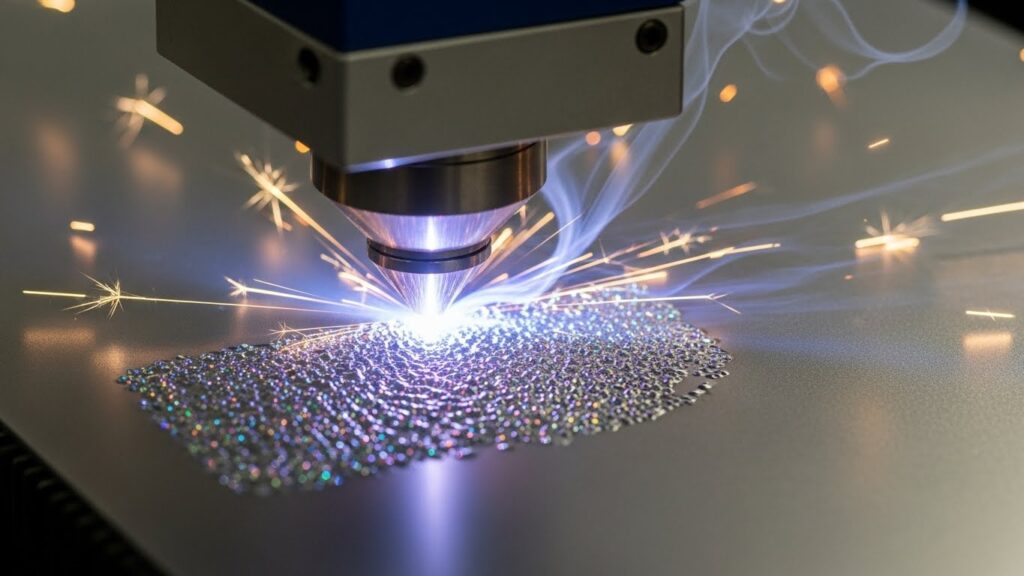

Creating a uniformly carved surface at a precise scale requires technology that transcends traditional craftsmanship. While hand-carving still has its place for unique artistic pieces, achieving industrial-grade precision-textured throughout results relies on sophisticated processes.

CNC Machining and Engraving: Computer Numerical Control allows for the most direct form of carving. Using diamond-tipped tools, mills, or lasers, a CNC machine can cut incredibly complex and consistent patterns into metals, plastics, and composites with micron-level accuracy. This is ideal for creating functional textures like fluid channels or optical diffraction gratings.

Chemical Etching: This subtractive process uses controlled chemical reactions to eat away material. By masking parts of the surface, manufacturers can create intricate, burr-free textures on even the hardest metals. It is particularly valuable for parts that cannot tolerate the mechanical stress of cutting, such as thin blades or delicate sensors.

Additive Manufacturing (3D Printing): This represents a paradigm shift. Instead of carving away, texture is built-in layer by layer. This allows for unprecedented complexity, including internal textures and topologies that would be impossible to achieve with any subtractive method. Lattice structures, which are lightweight yet strong, are a prime example of a precision-textured form created throughout a volume, not just on its surface.

Laser Texturing and Ablation: High-powered lasers can alter surface morphology with extreme precision. They can create micro-pores for adhesion, generate hydrophobic or hydrophilic patterns, or even change the color of a metal through controlled oxidation—all without any physical contact with the material.

The Sensory Experience: Texture in Product Design

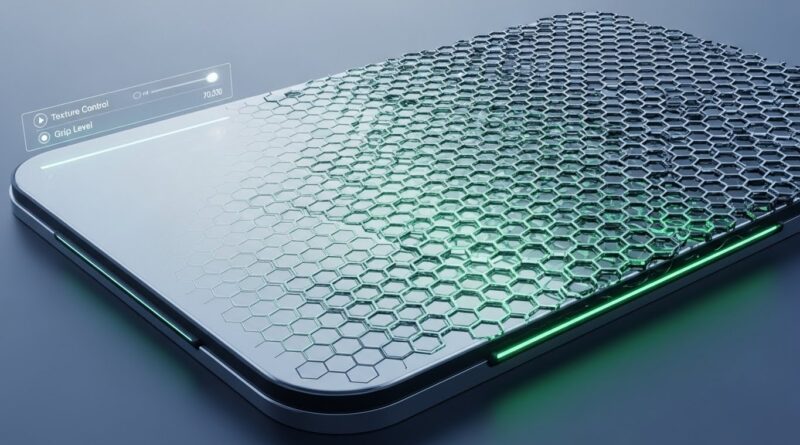

In our daily lives, the impact of carved surfaces is most directly felt through product design. The shift from smooth, glossy plastics to matte, textured finishes is more than a trend; it’s a response to the human desire for sensory connection. A smartphone with a precision-textured back glass is not only more beautiful as it plays with light, it is also more grippable and resistant to fingerprints. A tool handle with an ergonomically carved surface provides confidence and safety, communicating durability and control through touch alone.

This is where aesthetics and function merge seamlessly. The texture is the experience. Designers speak of “haptic feedback”—the tactile response a device gives. A finely carved button, with a distinct click feel achieved through its surface and underlying mechanism, creates a sense of quality and reliability. This meticulous attention to surface detail throughout a product’s interface builds an intangible trust in the brand. It signals that no detail was too small to be considered, engineered, and perfected.

Architectural Scale: Textures That Define Space

The philosophy of precision-textured throughout scales magnificently to architecture. Here, carved surfaces define atmospheres, manipulate acoustics, and play with natural light. Consider a facade clad in panels with a rhythmically textured pattern. Throughout the day, the moving sun will animate this surface, creating a dynamic play of shadow and highlight that makes the building feel alive. This is not a stamped-on pattern; it is a texture carved or formed into the material itself, ensuring consistency and durability against the elements.

Internally, textured walls or ceilings—from board-formed concrete with its wood-grain imprint to acoustical panels with sound-absorbing geometric perforations—serve critical roles. They break up sound reflections, add visual warmth to large spaces, and guide the flow of movement. The texture becomes an integral part of the spatial narrative, inviting touch and closer inspection, transforming a wall from a mere barrier into an experience.

The Future: Biomimicry and Smart Surfaces

The next frontier for carved surfaces lies in looking to nature and integrating intelligence. Biomimicry—the imitation of natural models—is a rich source for precision textures. The lotus leaf’s self-cleaning surface, the shark skin’s drag-reducing denticles, the moth eye’s anti-reflective nanostructures—all are examples of natural surfaces textured throughout for optimal performance. Engineers are now replicating these biological blueprints at scale, creating paints that resist fouling, aircraft wings that reduce fuel consumption, and solar panels that capture more light.

Furthermore, the convergence of texturing with smart materials is imminent. Imagine a surface whose texture can change on demand—smooth one moment for cleaning, grippy the next for handling. Or a catalytic surface with a specific nano-texture that maximizes chemical reactions for clean energy production. The “precision-textured throughout” surface of the future will be dynamic, responsive, and deeply integrated with the object’s core function, moving from a static state to an active interface.

Conclusion: The Integral Nature of Surface

The pursuit of the perfectly carved surface reminds us that there is no true separation between an object and its skin. The surface is not a wrapper; it is the point of interaction, the mediator between the internal purpose and the external world. “Precision-textured throughout” is the commitment to honoring that interaction at every level. It is a rejection of the superficial in favor of the integral, where beauty is a byproduct of purpose, and touch is as important as sight.

From the microscopic ridges on a biometric sensor to the grand, textured facade of a building, this principle is reshaping our material world. It asks designers and engineers to think deeper, to consider not just the shape of an object, but the detailed topography of its interface. In doing so, they create objects that are more useful, more durable, more sustainable, and ultimately, more human. The carved surface, in its perfected, uniform texture, tells a story of intention—a story carved not in stone alone, but in metal, polymer, and composite, throughout.